Bearing Technology Advancements

Bearing Technology Advancements

Blog Article

Bearing Technology Advancements

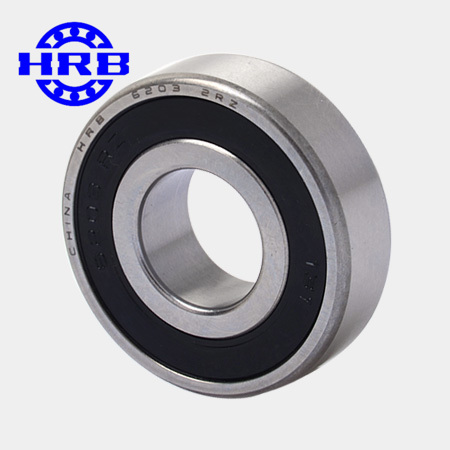

In the ever-evolving world of engineering and machinery, bearing technology advancements play a crucial role in improving the efficiency and performance of various applications. Bearings are essential components that facilitate smooth motion by reducing friction between moving parts. With constant innovations and developments in materials, design, and manufacturing processes, bearings have become more reliable, durable, and capable of handling higher loads and speeds.

Advancements in bearing technology have led to the development of specialized bearings tailored to specific industries and applications. For instance, industries such as aerospace, automotive, and renewable energy have benefited from bearings that offer increased precision, reduced weight, and improved corrosion resistance. These advancements have not only enhanced the performance of machinery but have also contributed to overall operational efficiency.

Companies like Www are driving innovation in bearing technology through their research and development efforts. By investing in cutting-edge technologies and materials, they continue to push the boundaries of bearing performance, meeting the evolving demands of modern engineering challenges.

The Importance of Choosing the Right Bearing Type

When it comes to selecting the right bearing for a specific application, engineers and designers must consider various factors such as load capacity, speed, operating conditions, and environmental factors. Choosing the wrong type of bearing can result in premature failure, increased maintenance costs, and downtime.

For example, in heavy-duty applications where high radial and axial loads are present, tapered roller bearings are preferred due to their ability to handle such loads efficiently. On the other hand, spherical roller bearings are ideal for applications with misalignment issues or heavy shock loads. Understanding the unique characteristics of each bearing type is essential for optimizing performance and ensuring longevity.

Moreover, advancements in bearing materials, such as ceramic and hybrid bearings, have further expanded the options available to engineers. These materials offer benefits like higher temperature resistance, increased corrosion resistance, and enhanced durability, making them suitable for demanding applications in industries like robotics, medical devices, and industrial machinery.

Do You Need to Purchase Bearings?

Whether you are a maintenance professional, a design engineer, or a hobbyist working on a project, having a good understanding of bearings is essential. Different applications require different types of bearings, and knowing the basics can help you make the right choice.

When considering the purchase of bearings, it is crucial to assess not only the type of bearing needed but also factors like lubrication requirements, sealing options, and installation considerations. Choosing the right bearing supplier is equally important, as it ensures you receive high-quality products that meet your specific application requirements.

For instance, reputable manufacturers like Www offer a wide range of bearings, including specialty bearings designed for extreme conditions or custom applications. By partnering with a trusted supplier, you can access technical expertise, product customization options, and reliable support throughout the bearing selection and implementation process.

Investing in quality bearings from reputable manufacturers can have a significant impact on the performance and longevity of your machinery or equipment. High-quality bearings are engineered to deliver consistent performance under challenging conditions, reducing the risk of unexpected failures and costly downtime.

In conclusion, bearing technology advancements continue to drive innovation in various industries, providing engineers and designers with advanced solutions to improve efficiency and performance. By choosing the right bearing type and investing in quality bearings, you can enhance the reliability and durability of your applications while minimizing downtime and maintenance costs.

Report this page